How NC State Advances Food Manufacturing

Photo credit: NC State University

More than 1,000 food and beverage manufacturing operations already call North Carolina home. Yet, experts see untapped food-processing potential in a state ranked No. 2 for its business-friendly climate and No. 3 for diversity of agricultural products.

North Carolina provides a great place to do business and add value to over 90 crops grown in the state, according to statistics from the NC Food Innovation Lab.

“It’s time for North Carolina to take a leadership role in food processing,” says Dr. K.P. Sandeep, head of North Carolina State University’s Department of Food, Bioprocessing & Nutrition Sciences. “We have the commodities, the soil and the water, and we also have the know-how in terms of the people. I hope North Carolina can become a leader in food processing in the next couple of decades.”

Making Advancements

In the food-making realm, NC State has earned a reputation for advanced aseptic processing and packaging. This processing technology sterilizes products with continuous-flow microwave heating, making the food products shelf-stable while retaining more of their color, flavor and nutritional value. The technology challenges widely used sterilization processes in the industry. It also disputes conventional thinking, which generally pegs processed foods as less nutritious.

“My hope and ambition is to have North Carolina become a technology provider and leader in value-added processing, especially of shelf-stable products,” says Josip Simunovic, an NC State research professor who has secured 19 U.S. patents and dozens of international patents. “The technology can accelerate the commercial relevance of our crops. It works as motivation to educate students and people at other companies throughout the country – and potentially the world – to accept these innovations.”

Beyond inspiring others, the technology promotes products that are rich in vitamins, antioxidants and other nutrients in short supply worldwide because they get degraded and destroyed by outdated processing methods.

Success Stories

Simunovic has co-founded seven companies, including SinnovaTek Inc., which develops technologies and systems that retain the natural goodness of food. Several North Carolina companies use the processing technologies developed by his program, including Ripe Revival, which makes protein-rich gummies. Another success story is Yamco, a group of sweet potato growers who use this processing technology to make high-quality puree for baby foods, baked goods and even Covington Gourmet Vodka from misshapen sweet potatoes.

“Yamco preserves 98% of vitamin A, which is globally under-consumed,” Simunovic says. “The technology has helped these farmers capture a market for the 40% of sweet potatoes previously considered unmarketable due to their size or shape.”

SinnovaTek’s latest venture is FirstWave, a precision-scale aseptic food copacking facility for business owners to test new products without the typical minimum order quantities required for a launch. As with Yamco, it also helps lessen food and farm waste by using byproducts.

“Amid the pandemic, we have seen a large gap between food excess on farms and the need for food assistance in communities,” says Amanda Vargochik, SinnovaTek co-founder & VP of Innovation. “With FirstWave, we can help bridge that gap with a unique model that is built with agility in mind. We have the capacity to breathe new life into food ingredients by upcycling food waste and to support small businesses by giving them an avenue to create a value-added product without the risk of large scale.”

See more: North Carolina Researchers Study Foods to Fight Allergens and More

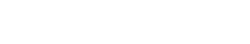

A variety of local food products, including 1in6 Snacks’ Carolina Kettle chips, were created by entrepreneurs who participated in NC State food manufacturing programs. Photo credit: Raphael Rogers/Carolina Kettle

Small-business owner Josh Monahan also intends to make his mark. The NC State graduate founded 1in6 Snacks, which markets Carolina Kettle chips, among other snack foods.

“My family has been in the snack food industry for 65 years,” Monahan says. “North Carolina, in general, is a good place to do business. We have so many good retailers in this area that are good partners, and it makes it easy to be in the snack food industry.”

Monahan named the business after the statistic that one in six Americans have food-security concerns. Each purchase of Carolina Kettle chips generates a donation to local food banks. As of mid-2020, Monahan says his company has donated the equivalent of 225,000 meals.

Photo credit: Todd Bennett

A Community of Support

Since 1992, the Entrepreneur Initiative for Food (EI4F) program at NC State has helped small businesses in North Carolina navigate state and federal regulations for food safety, a daunting and often expensive task for new businesses. The program offers its services at a reduced cost, helping cash-strapped startups enter the food-processing industry.

“I think this program is critical to North Carolina and other states for their entrepreneurs,” says Nick Fragedakis, who leads EI4F. “The testing and evaluations that we offer are a fraction of the cost. Also, having phone conversations with clients to help them navigate state and national regulations for food safety is a huge help.”

See more: How One Couple Is Engineering a Better Farm

The program’s popularity, particularly with acidified foods such as pickles, chutney and pepper jams, has led to nationwide training and testing services, Fragedakis says. The program’s online acidified foods course has enrolled participants around the world, and entrepreneurs throughout the state and nation annually send upward of 1,000 processed food samples for testing at the lab.

Photo credit: Carl Hollifield

Education Drives Industry

The NC State Department of Food, Bioprocessing & Nutrition Sciences offers several degree programs and delivers online food certification classes for even nondegree students. The department houses national centers that study advanced processing and packaging techniques. Students and staff in the department also process dairy foods, including the well-known Howling Cow ice cream.

Learn more about how to get involved with North Carolina State University’s Department of Food, Bioprocessing & Nutrition Sciences at fbns.ncsu.edu.See More

NC State proudly partners with the NC Food Innovation Lab, a governor-prompted project that opened in 2019 and hopes to accelerate food processing in the state.

“The idea of this Food Innovation Lab is for us to mainly help local farmers convert their raw commodities into a value-added food product within state lines,” Sandeep says. “We are hoping these types of successes will bring even more success stories little by little and result in more food-processing ventures within North Carolina.”

– Joanie Stiers

North Carolina Field and Family magazine highlights farms and foods, events and attractions, and interesting people and places throughout the state.

North Carolina Field and Family magazine highlights farms and foods, events and attractions, and interesting people and places throughout the state.

Pingback: judi bola

Pingback: press release distribution press release